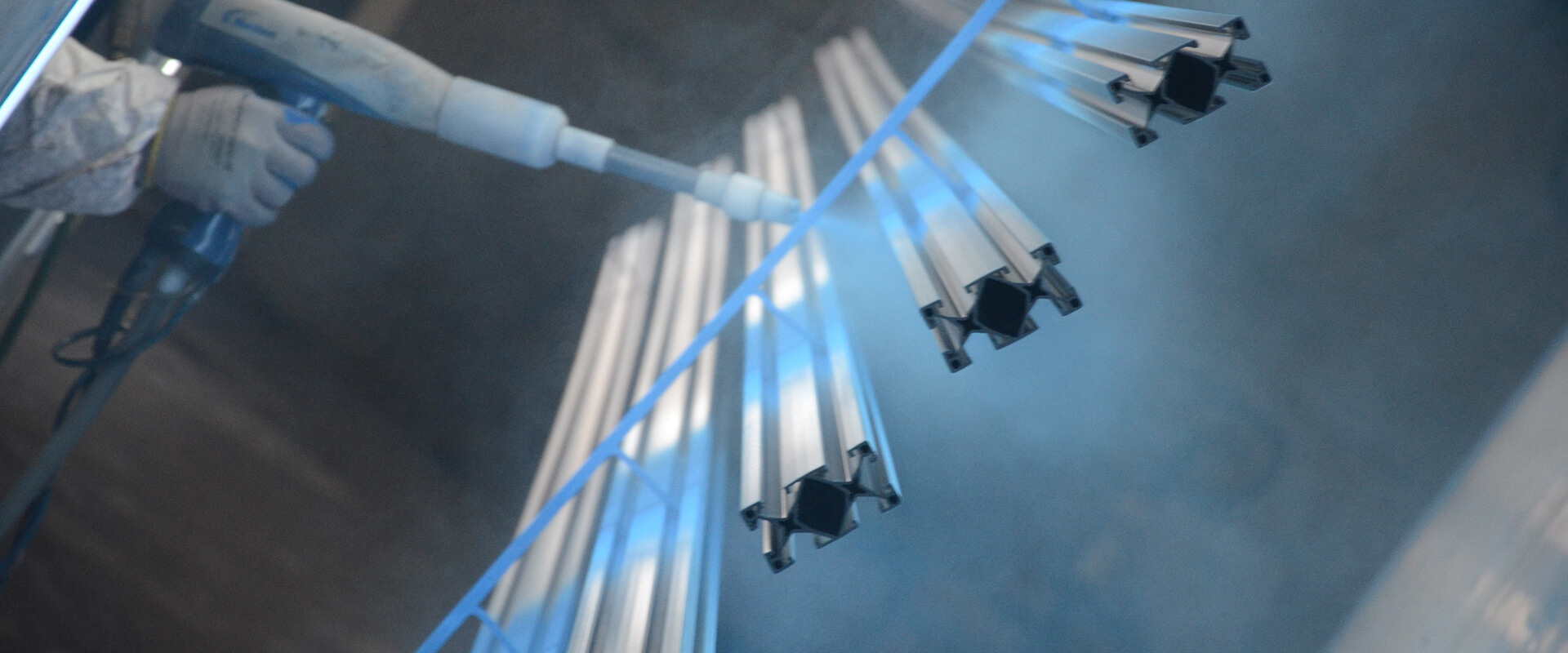

The roller conveyor is a shot blasting machine that treats long or flat components by passing them through preparation, blasting and cleaning chambers on a roller conveyor belt.

The specifications for our roller conveyor blaster include:

- Height: 17 inches

- Width: 48 feet

- Length: 30 feet

- Media: Grit blast