Heat-resistant powder coatings are a specialized category of protective coatings that can thwart high temperatures while providing long-lasting performance in environments where extreme weather is a constant challenge. These coatings have exceptional resistance against heat-induced degradation, adding to their appeal in various applications.

This product can maintain its structural integrity and appearance in a variety of circumstances, making it the go-to choice for domestic and industrial applications where surfaces or components frequently encounter a lot of heat. Understanding the various types of powder coating, their applications and which industries they thrive in will help the end user make informed decisions about which type to invest in for their products.

Understanding Heat-Resistant Powder Coating

One key difference between powder coatings and paint is that the former is applied in its solid form and does not emit volatile organic compounds (VOCs). Heat-resistant coatings are specialized, protective finishes that can withstand heightened temperatures. These coatings ensure that coated surfaces maintain their appearance and integrity in most temperatures and environmental conditions. They form a formidable barrier when used as a dry powder and cured in baking.

The primary purpose of heat-resistant coatings is to protect surfaces from damage due to heat, deterioration, corrosion and discoloration in the following industries and more:

- Agriculture: Here heat-resistant powder coatings protect from weather elements.

- Aluminum extrusions: This product improves the appearance and durability of aluminum extrusions.

- Architecture: Heat-resistant coatings feature in building materials, landscaping items, windows and doors.

- Commercial automotive: Besides protection, it strengthens products like brackets, coil springs and engine covers.

- HVAC: This coating adds strength and prevents corrosion in these systems.

- Industrial: Powder coating adds durability to various industrial applications.

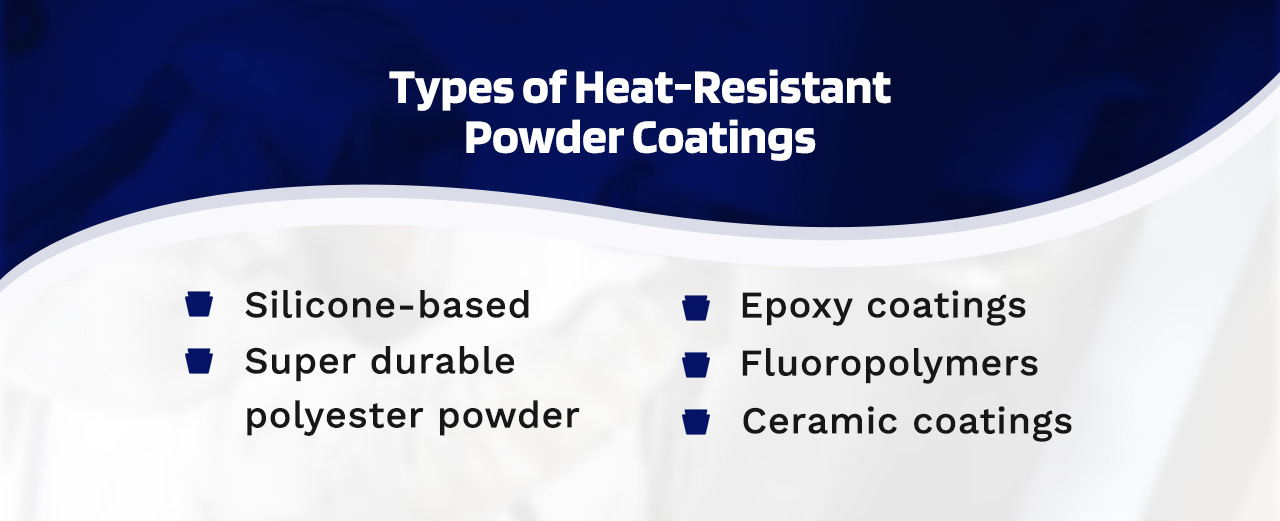

Types of Heat-Resistant Powder Coatings

These powder coatings can resist high temperatures in various applications by incorporating heat-resistant silicone resins. While there is not necessarily a ‘best’ heat-resistant coating, several types of heat-resistant powder coatings are on the market, each with its optimal application use:

- Silicone-based: This powder coating offers great heat resistance and works well in industrial machinery and automotive exhaust systems applications.

- Super durable polyester powder: This product is made to withstand demanding environments and harsh climates. It improves finishing thanks to ultraviolet light and corrosion resistance.

- Epoxy coatings: With generally good abrasion and impact resistance, this type is seen in industrial applications, electrical components and petrochemical facility applications.

- Fluoropolymers: Often finding use in the architectural sector and non-stick cook or bakeware, this powder coating has excellent weatherability and chemical and abrasion resistance.

- Ceramic coatings: This coating has extreme temperature resistance and can find use as a thermal insulator in automotive, industrial and aerospace industries.

Temperature Tolerance

With powder coating complementing materials like aluminum, iron, steel and zinc alloy, temperature tolerance is a critical factor. The performance of heat-resistant powder coatings in terms of thermal reading, depends on the makeup and end use of the powder coating product. Generally, temperature resistance sits comfortably at 0 degrees Fahrenheit and extends to 200 degrees Fahrenheit, with intermittent spikes between 350 and 400 degrees Fahrenheit.

Application Process

There are several steps to the application of powder coatings. Throughout these procedures, it is vital to set safety precautions to protect workers from harmful chemicals and ensure an overall safe working environment. The application process involves several key steps to provide an effective and durable finish:

- Blasting: This preparation prevents bubbling, cracking and moisture build-up post-application. Professional abrasive blasting removes debris or liquids that can curb a strong bond and smooth finish when applying the powder coating. It also creates micro textures on metal surfaces to promote a secure bond with the primer and powder.

- Masking: Masking is a vital step that uses advanced products with precise techniques to protect areas on products that need to steer clear of the powder coating. This can include screws, holes or mechanical parts.

- Pretreatment: A powder coating cleaning process that prepares surfaces, ensuring they are free from residue, better prepares them for heat-resistant powder coating applications.

- Primer: Priming provides a layer of protection to products while strengthening the bond with powder coatings. The primer can help to prevent oxidation and rust.

- Coating: The powder coating loads into a spaying system, which adheres to a primed product exterior.

- Curing: Powder coating curing takes place in an industrial oven. The temperature depends on variables like the powder type, thickness and other order specifications.

- Testing: Following the curing process, products undergo rigorous testing to ensure uniform powder coat adhesion, millage and visual appearance.

- Assembly, packaging and shipping: Where needed, products are put back together following client guidelines. Products are packaged safely and shipped to the client directly from the service center.

Performance Characteristics

Heat-resistant powder coatings have a few key performance characteristics that add to their value in industrial and domestic applications. Apart from their heat resistance, they also offer protection against chemicals, environmental factors and corrosion. Users can choose from various finishes and colors for long-lasting performance and aesthetic appeal.

Maintenance and Durability

While this product is made to withstand high temperatures and extreme environmental impacts, it is essential to properly care for products with heat-resistant coatings to support their durability. The durability of these coatings largely depends on factors like application quality, coating formulation and exposure to extreme heat and environmental fluctuations. These coatings have been reported to withstand 1,000 hours of a salt spray test on airplane parts with no clear indication of corrosion. Regular inspections will help detect any potential signs of wear or chipping.

Maintenance on heat-resistant powder coatings can involve recoating areas with cracks or doing touch-up work. Stay away from cleaning this coating with harsh chemicals or abrasive cleaners, as that can damage the coating. Gently rinse with mild, soapy water and a soft brush and dry the surface after cleaning. Generally, the coating should keep its appearance and integrity for several years with proper maintenance.

Powder Coating Services With Keystone Koating

Heat-resistant powder coatings are a formidable solution to help safeguard surfaces against extreme temperature conditions. From automotive exhaust systems and household appliances to industrial machinery and architectural applications, these coatings add to the durability and protection of surfaces under demanding circumstances.

Keystone Koating offers powder coating services from start to finish. Our comprehensive powder coating process is fully customizable and includes preparation, blasting, packaging and shipping. We offer high-quality work, quick turnaround times and excellent customer service. With over 35 years of industry experience, we can offer experienced consulting and training services to improve your profitability.

Request a quote to see how Keystone Koating will benefit your business.