The Salt Fog Cabinet tests corrosion resistance of coated metal panels.Keystone Koating’s facilities provide tests needed for stellar metal coating processes. Keystone Koating’s innovative powder coating process includes an attribute many other facilities don’t have: a Quality Assurance Lab, with a Salt Fog Cabinet and four-step testing program.

Salt Fog Cabinet

The Salt Fog Cabinet, which tests the corrosion resistance of coated metal panels, enables lab technician Jason Weaver to compare various primers and pretreatments and determine which offer the best protection for various metal surfaces. His research follows the American Society for Testing and Material technical standards.

“The Salt Fog Cabinet is the workhorse of our lab,” says Sylvan Martin, Systems Manager at Keystone Koating. “Salt spray tests create an accelerated corrosive environment and the cabinet provides a tightly controlled environment,” he explains.

“The panels are coated on the line. I’ll pick a group with the powder coating millage close to spec, and I’ll scribe them to expose the metal,” Weaver explains. He’ll then place them in the Salt Fog Cabinet.

After a prescribed time lapse, under which the panels are kept in a salty fog at 95 degrees, Weaver examines the rust creep on each panel and rates the performance of the coating. He’ll measure the creepage, after subjecting the rust lines to a steel scraper and air gun. He then gets a mean rating from averaging measurements taken from three locations on the metal, along the scribe line.

Keystone Koating uses only powder coatings that receive the best of those ratings.

Crosshatch Adhesion Test

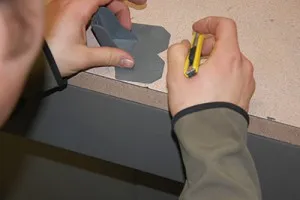

Other laboratory work includes a crosshatch adhesion test, in which Weaver makes 6 small cuts vertically and 6 small cuts horizontally in the metal coating to see if any squares of coating come off or if any flaking occurs.

Boiling Water Test

The Quality Assurance Lab also has the means to conduct a boiling water test in which metal panels are placed in heat stress for 20 minutes to test adhesion.

“The boiling water test is just another way to be harder on your coating to see if it will hold up,” Martin says.

MEK Test

An MEK (methyl ethyl ketone) test is done to determine solvent resistance and how well the coating cured in the oven.

Weaver also uses the lab to test new technology, new pretreatment chemicals, A/B degradation testing, and to troubleshoot any coating issues.

“The lab tests advance our pretreatments,” Weaver adds.

Additional, Standard Testing

This Quality Assurance Lab is in addition to numerous standard tests – which include a manual fingerpress test, crosshatch test, MEK test, millage reading, another manual contact test, and a visual inspection – all done while products are still on the coating line, and documented in a Quality Control Check Sheet.